Grasping Gauge Fillet Welds: Tips for Perfect Measurements and Implementation

Grasping Gauge Fillet Welds: Tips for Perfect Measurements and Implementation

Blog Article

Cutting-edge Methods to Fillet Weld Inspection and Testing: Enhancing Weld Top Quality and Compliance Standards

In the realm of welding, the top quality and integrity of fillet welds play a crucial role in making certain the architectural strength and integrity of various commercial components. With the consistent drive for improved efficiency and conformity with rigid requirements, the expedition of cutting-edge strategies to fillet weld examination and screening has actually ended up being imperative. As sectors progress, the standard methods may no more be enough in fulfilling the demands of modern welding applications (Gauge Fillet Weld). By welcoming advanced technologies and methods, a new horizon of opportunities arises in the world of weld high quality evaluation and adherence to conformity criteria.

Advanced Non-Destructive Testing Approaches

Utilizing cutting edge modern technologies, advanced non-destructive testing techniques play a critical function in making sure the honesty and top quality of fillet welds. These methods, such as phased selection ultrasonic testing (PAUT) and magnetic particle testing (MPT), offer comprehensive insights right into the weld's interior structure without creating any kind of damage to the product. PAUT, as an example, uses multiple ultrasonic aspects to inspect the weld from different angles, offering a thorough visualization of potential problems like absence of combination or fractures.

Similarly, MPT is effective in spotting surface-breaking flaws by applying an electromagnetic field and iron bits to the weld location. This approach is especially beneficial for recognizing suspensions that may compromise the weld's strength. By utilizing these advanced non-destructive testing techniques, weld examiners can precisely evaluate the high quality of fillet welds, making certain conformity with sector requirements and policies. The ability to find problems beforehand not just improves weld high quality however additionally stops costly rework or failings in architectural stability, underlining the value of these ingenious screening strategies in welding assessments.

Robotics and Automation in Inspection

The integration of robotics and automation has revolutionized the examination procedure for fillet welds, improving effectiveness and accuracy in top quality evaluation. Robotics supply accurate control and repeatability in evaluating welds, making certain regular and reliable results. Automated systems can be set to follow details assessment courses, making sure detailed insurance coverage of welds and minimizing the danger of human mistake.

Robotic inspection systems furnished with advanced sensors can find and gauge weld features with high accuracy, supplying detailed information for analysis. These systems can recognize flaws such as cracks, lack of combination, and porosity, allowing prompt corrective activities to be taken. Furthermore, robotics and automation enable real-time data collection and analysis, giving prompt responses to operators and helping with fast decision-making processes.

Additionally, the usage of robotics and automation in fillet weld assessment improves total efficiency by lowering inspection times and increasing examination throughput. By enhancing the evaluation process, makers can ensure weld quality and compliance requirements are fulfilled successfully, inevitably bring about set you back financial savings and enhanced item top quality.

Utilizing Expert System for Analysis

Artificial knowledge plays a crucial role in enhancing the efficiency and precision of analysis in fillet weld assessment processes. By harnessing the power of AI, examiners can improve the analysis of weld quality and conformity criteria, leading to much more dependable and specific results. AI algorithms can swiftly process large quantities of information from weld assessments, discovering problems he said or inconsistencies that may be testing to understand the nude eye. This innovative innovation enables real-time monitoring of weld top quality, enabling instant corrective actions to be taken if any type of concerns are identified.

Furthermore, AI systems can gain from previous inspection data, constantly enhancing their capability to recognize possible issues and deviations in fillet welds. This adaptive discovering capability improves the general quality control process, decreasing the possibility of human error and guaranteeing that welds meet the required standards. By incorporating synthetic intelligence right into fillet weld evaluation, industries can attain higher levels of effectiveness, uniformity, and conformity in their examination methods.

Portable Devices for On-Site Assessment

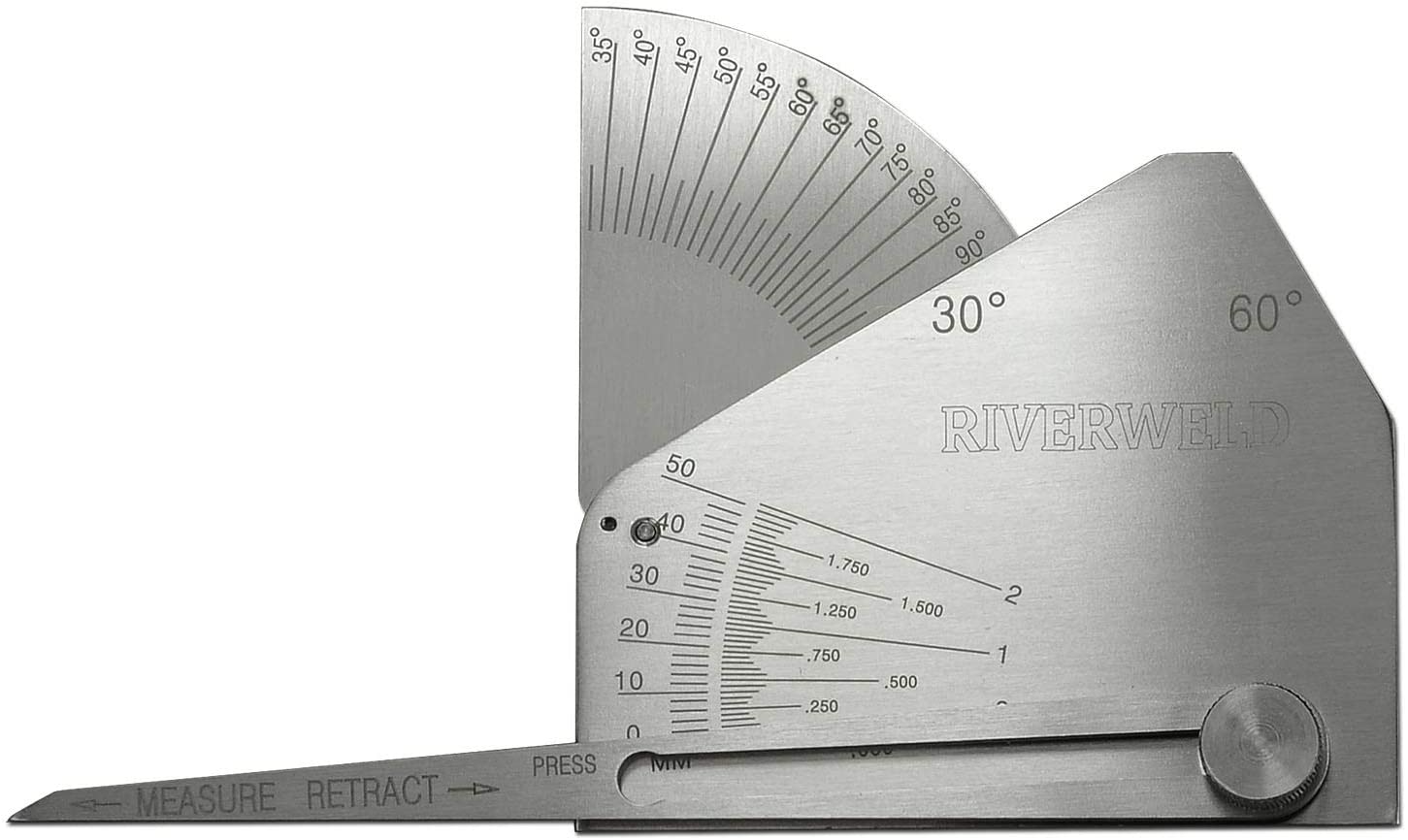

Enhancing field examination effectiveness, the fostering of mobile tools transforms on-site evaluation procedures for fillet welds. These devices provide flexibility and benefit, allowing assessors to conduct thorough evaluations in various areas, including remote or difficult settings. Mobile tools such as ultrasonic testing devices, magnetic fragment evaluation tools, and electronic radiography systems supply real-time data and high-resolution imaging capabilities, allowing quick decision-making and immediate responses on weld top quality.

One considerable advantage of visit our website portable devices is their ability to simplify inspection procedures, minimizing downtime and improving overall efficiency - Gauge Fillet Weld. Examiners can conveniently carry these devices to various job websites, getting rid of the demand for transferring hefty equipment or components to off-site facilities. Additionally, the mobility of these tools promotes cost-effectiveness by lessening transportation expenses and increasing assessment timelines

Furthermore, the use of mobile tools for on-site assessment promotes proactive high quality control measures, as examiners can promptly determine and resolve any type of prospective welding flaws or discrepancies. By incorporating these ingenious modern technologies into on-site assessment practices, welding experts can guarantee conformity with market requirements and boost weld quality, eventually bring about improved structural integrity and security in various welding applications.

Integration of Data Administration Equipment

Having optimized on-site examination procedures with the usage of portable devices, the following stage includes the smooth assimilation of information monitoring systems to even more boost performance and data evaluation capacities in fillet weld examination and screening. By integrating information monitoring systems right into the evaluation process, organizations can streamline data collection, storage, and analysis. This combination enables for real-time monitoring of weld top quality, immediate recognition of issues, and timely decision-making to fix any kind of concerns that may emerge during the examination process.

The integration of information monitoring systems makes it possible for seamless communication in between different stakeholders involved in the assessment procedure, fostering collaboration and enhancing total high quality control measures. Ultimately, the assimilation of information monitoring systems serves to boost the requirements of fillet weld evaluation and screening, making sure compliance with market regulations and boosting weld high quality.

Final Thought

In conclusion, cutting-edge approaches to fillet weld examination and testing have substantially enhanced weld quality and compliance requirements. Advanced non-destructive testing approaches, robotics, automation, synthetic intelligence, portable devices, and information management systems have actually transformed the means weld evaluations are carried out. By using these innovations, industries can guarantee that welds meet the required top quality standards and laws, ultimately enhancing general effectiveness and security in welding processes.

Having actually enhanced on-site inspection processes through the application of portable devices, the next phase includes the seamless integration of information administration systems to even more boost effectiveness and data analysis capacities in fillet weld assessment and screening. Ultimately, the pop over here integration of data management systems offers to boost the criteria of fillet weld inspection and testing, making sure compliance with sector guidelines and boosting weld quality.

Report this page